The Importance of Precision in Heavy duty and Industrial Gears

Precision engineering in industrial gears is essential for maximizing machine performance, reliability, and energy efficiency.

In industries such as cement, mining, and heavy manufacturing, the quality of gear manufacturing directly impacts operational success, cost savings, and equipment longevity.

How Precision Engineering Improves Gear Performance

In heavy industry, gears are often described as the “heart” of machines. From cement plants to mining operations, precision industrial gears transmit enormous forces and keep critical processes moving. When gears are manufactured with exact tolerances, they ensure:

- Smooth machine operation

- Reduced downtime

- Optimal energy use

Even minor deviations in gear geometry or alignment can cause inefficiency, noise, and premature wear. That’s why precision engineering is not just a technical detail—it’s a strategic factor that drives industrial success.

Gear Geometry Testing for Continuous Improvement

At MAAG Gear, we are committed to continuous innovation and quality assurance. We regularly test gear geometries on our machines to ensure optimal performance and reliability. By analyzing how different tooth profiles and configurations behave under real-world operating conditions, we can:

- Further reduce vibration and noise

- Maximize load-carrying capacity

- Extend gear service life

- Identify opportunities for design improvements

This hands-on approach to gear geometry testing allows us to validate our engineering solutions and deliver gears that meet the highest standards of precision and durability. It also ensures that our customers benefit from the latest advancements in gear manufacturing technology.

The Role of Precision in Gear Efficiency and Reliability

The accuracy of a gear’s tooth profile, spacing, and surface finish directly determines how efficiently power is transmitted. Precisely engineered gears:

- Minimize vibration and friction

- Deliver torque without unnecessary energy loss

- Reduce maintenance intervals and unplanned downtime

Example: Bevel gear sets produced by MAAG Gear use advanced tooth geometries such as palloid and cyclo-palloid profiles. This results in smoother contact, reduced noise, and longer service life—demonstrating how precision engineering directly impacts industrial performance.

Reducing Operational Costs with High-Precision Gears

Precision in gear manufacturing plays a decisive role in reducing energy consumption and operational costs. When gears mesh perfectly:

- Less energy is wasted through heat, vibration, or friction

- Maintenance intervals are extended

- Lifecycle costs are minimized

Custom-made gear solutions, tailored to specific operating conditions, further enhance machinery efficiency by optimizing materials, heat treatments, and gear geometries.

Durability and Reliability in Harsh Environments

Industrial machines often operate under cyclic loads and in abrasive environments. Even microscopic imperfections in gears can lead to fatigue cracks, accelerated wear, or catastrophic failure. High-quality manufacturers apply stringent quality controls, including:

- Non-destructive testing (ultrasonic, magnetic inspections)

- Controlled heat treatment processes

At MAAG Gear, every gear undergoes rigorous checks to ensure reliability and durability, even under extreme stress.

Safety and Performance in Demanding Applications

In sectors like cement, mining, and heavy industry, gears and drive systems face extreme loads, dust, temperature fluctuations, and abrasive conditions. In these environments, precision and reliability are essential for both safety and performance.

MAAG Gear offers a comprehensive portfolio of high-performance products designed for these demanding applications, including:

- Gears for Vertical Roller Mills (e.g., MAAG® GEAR, WPV, WPU, MAX Drive, IronDrive)

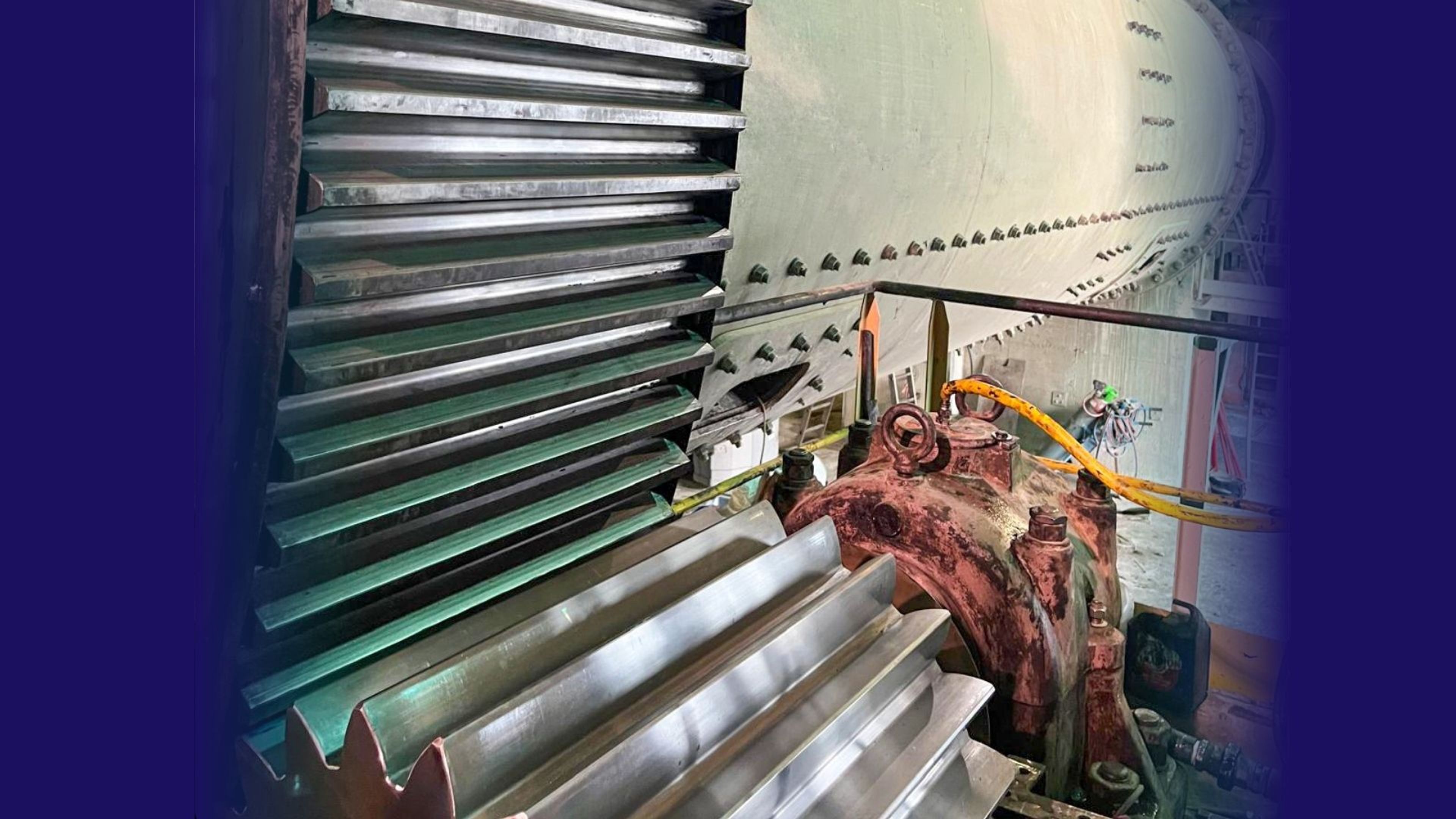

- Gears for Ball Mills, SAG Mills, and Horizontal Mills

- Girth Gears and Pinion Drives

- Gear Pumps and Industrial Gear Units

- Replacement Kits and Aftermarket Solutions

Precisely manufactured bevel sets, girth gears, and gear units from MAAG are built to absorb high stresses while maintaining smooth operation. Their high load-bearing capacity and fine tooth accuracy ensure reliable performance where failure would be catastrophic.

Advanced quality controls, digital monitoring, and predictive maintenance solutions further enhance operational safety, helping to prevent unplanned downtime and protect both people and equipment.

The Future of Precision Gear Technology

The future of industrial gearing is inseparable from precision. Key trends include:

- Digital monitoring systems for real-time tracking of vibration, temperature, and wear

- Predictive maintenance strategies to reduce costly failures

- Advances in materials science and machining for tighter tolerances

- Technologies like hard finishing and precision skiving for smoother surfaces and more accurate tooth geometries

Companies like MAAG Gear are leading the way by combining traditional robustness with modern intelligence, delivering a new generation of high-quality gears for maximum performance and efficiency.

Conclusion: Why Precision Matters in Industrial Gears

The importance of precision in industrial gears cannot be overstated. From energy efficiency and operational safety to durability and cost savings, precision defines the difference between machines that “work well enough” and machines that achieve their full potential.

In industries where every hour of downtime means significant financial loss, investing in precision gear manufacturing is not a luxury—it’s a necessity.

Contact us today to learn more about our precision gear solutions, our gear geometry testing capabilities, or to request a quote for your next project.

Join our newsletter.

Don’t miss out on the latest news, updates,

and insights - from MAAG.

© copyright MAAG Gear 2025. All rights reserved.

MAAG GEAR

INDUSTRIES

SERVICE CENTER

INDUSTRIES

SERVICE CENTER