Predictive Maintenance for Industrial Gears

Extending Lifespan and Reducing Downtime with Smart Maintenance Strategies

In the world of heavy industry, where every second of machine uptime counts, predictive maintenance is rapidly transforming how companies approach the health and performance of their industrial gears. Gone are the days of reactive or purely scheduled servicing.

Today, with the integration of advanced analytics, condition monitoring, and real-time diagnostics, maintenance becomes smarter, more efficient, and profoundly more cost-effective.

For companies operating in demanding sectors like cement, mining, and energy production — where massive gear systems drive critical machinery such as horizontal mills, rotary kilns, and roller presses—the stakes are high. Equipment failure doesn't just mean repair costs.

It means downtime, production loss, supply chain disruptions, and reputational damage. Predictive maintenance aims to rewrite this narrative.

From Reactive to Proactive: A Shift in Mindset

Traditional maintenance approaches often rely on routine schedules or intervention after a breakdown. While this might seem methodical, it frequently leads to either over-maintenance — wasting resources and shortening component life — or under-maintenance, which increases the risk of catastrophic failures. Predictive maintenance strategies eliminate these inefficiencies by leveraging data to anticipate failures before they occur.

Companies like MAAG Gear, with decades of expertise in high-performance gearing systems, are at the forefront of implementing intelligent maintenance solutions. Their systems are often mission critical, built for extreme operating conditions and designed to endure high torque and thermal loads. Yet, even the most robust gears benefit greatly from a predictive approach that ensures continuous, optimal performance.

Smart Sensors and Data-Driven Insights

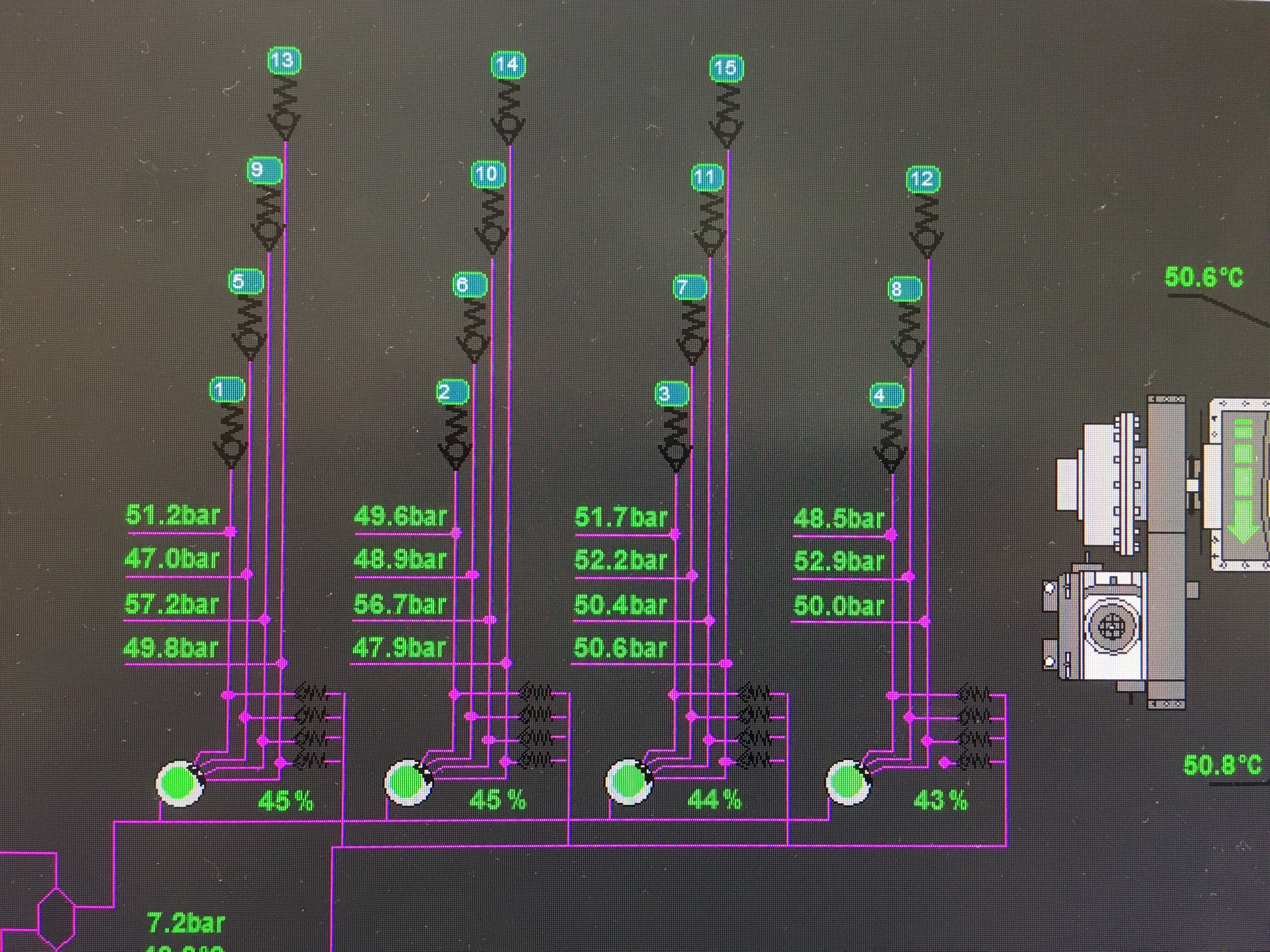

Modern predictive maintenance for industrial gears relies on a network of smart sensors installed on critical components. These sensors continuously monitor key parameters such as temperature, vibration, noise, and lubrication quality. Abnormalities or trends that deviate from established baselines trigger alerts, prompting a targeted inspection or intervention.

MAAG Gear integrates such technologies into its systems or retrofits them onto legacy equipment. Combined with diagnostic algorithms and machine learning, this data doesn't just highlight current issues — it forecasts future problems. The result is an ability to plan interventions with surgical precision, avoiding unnecessary shutdowns while protecting key assets from unplanned failure.

Reducing Downtime, Increasing Asset Lifespan

The central promise of predictive maintenance is downtime reduction. For industries where shutdowns cost thousands (or even millions) of euros per day, predictive systems are not just helpful — they're transformative. When a gear system, such as the MAAG® GEAR SYMETRO™ or PPU

unit, begins to show signs of wear, predictive diagnostics allow plant operators to plan maintenance during scheduled shutdowns, avoiding expensive emergency repairs.

Furthermore, because interventions are timed with actual wear and tear instead of arbitrary schedules, the lifespan of gear components is significantly extended. Lubricants are changed when necessary, not too early. Bearings are replaced before failure, but not prematurely. Over time, this approach translates to lower total cost of ownership and higher return on investment.

Maintenance Strategies Tailored to Each Application

Not all gear systems operate under the same conditions. High-load vertical mill gears face different stresses than kiln drives or roller press gearboxes. MAAG Gear recognizes that effective maintenance strategies must be customized, taking into account operating environment, load cycles, thermal conditions, and process dynamics.

This is why predictive maintenance is not a one-size-fits-all solution, but a framework — one that MAAG Gear supports with technical consulting, field inspections, and remote diagnostics. The company’s service teams provide detailed health reports and help plant managers fine-tune their maintenance practices based on real-time performance data.

The Human Factor and Digital Transformation

Predictive maintenance also represents a cultural and organizational shift. Plant personnel move from being crisis responders to proactive engineers. With clear dashboards and predictive alerts, they gain better control over complex systems and can focus their expertise on strategic interventions.

MAAG Gear supports this transition by offering training, integration with SCADA systems, and intuitive tools that bridge the gap between mechanical engineering and digital intelligence. This fusion of domain know-how and data science is what empowers companies to reach new levels of operational efficiency.

The future of industrial gear maintenance lies in ever deeper integration of digital tools, remote monitoring, and AI-powered analytics. MAAG Gear is already shaping this future by embedding intelligence into its systems and services, ensuring that customers not only maintain their gear units — but optimize them.

As industries continue to demand higher availability, lower costs, and greater sustainability, predictive maintenance will play an indispensable role. For operators of industrial gears, it’s not just a smart maintenance strategy. It’s a competitive advantage.

Join our newsletter.

Don’t miss out on the latest news, updates,

and insights - from MAAG.

© copyright MAAG Gear 2025. All rights reserved.

MAAG GEAR

INDUSTRIES

SERVICE CENTER

INDUSTRIES

SERVICE CENTER